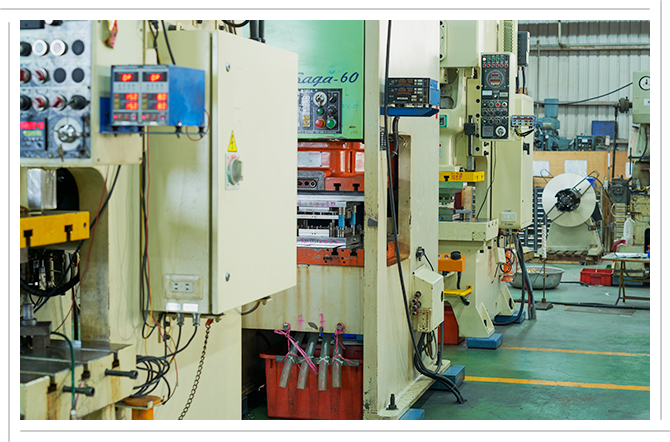

Yong-Mo mainly designs progressive dies and compound dies, and we are fully capable of independent design and development. In facing diversified, high-variation product types and rapidly changing product life cycles, we have a professional design and production team, a one-stop service that can create a product from product design, sampling, testing, die-sinking, to manufacturing based on the diagram or sample provided by the client. The factory is fully equipped, with a local content rate as high as 85%. For this reason, our product delivery timeline is stable and we provide outstanding quality. Our mission is to respond quickly to the various demands of the clients. In recent years, we continue to perfect ourselves and upgrade various production and inspection equipment in order to provide our clients with even higher quality and better design products.

We are highly commended by the industry for our strict control of die material requirements, die life, production speed, and stable quality.